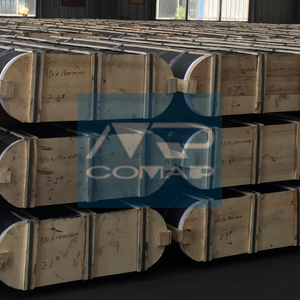

We are specialists in the import-export of graphite electrodes of all qualities and dimensions. Our manufacturing partners are ISO9001:2015 certified. The production plants use state-of-the-art technology and first-class raw materials. Our electrodes are strictly controlled to ensure high quality to our customers.

Find out more about our different graphite electrodes.

Notice: Function Elementor\Controls_Manager::add_control_to_stack was called incorrectly. Cannot redeclare control with same name "button_box_shadow_box_shadow_type". Please see Debugging in WordPress for more information. (This message was added in version 1.0.0.) in /var/www/vhosts/comap-sas.com/httpdocs/wp-includes/functions.php on line 5905

Notice: Function Elementor\Controls_Manager::add_control_to_stack was called incorrectly. Cannot redeclare control with same name "button_box_shadow_box_shadow". Please see Debugging in WordPress for more information. (This message was added in version 1.0.0.) in /var/www/vhosts/comap-sas.com/httpdocs/wp-includes/functions.php on line 5905

Notice: Function Elementor\Controls_Manager::add_control_to_stack was called incorrectly. Cannot redeclare control with same name "button_box_shadow_box_shadow_position". Please see Debugging in WordPress for more information. (This message was added in version 1.0.0.) in /var/www/vhosts/comap-sas.com/httpdocs/wp-includes/functions.php on line 5905

Notice: Trying to access array offset on value of type bool in /var/www/vhosts/comap-sas.com/httpdocs/wp-content/plugins/elementor/includes/base/widget-base.php on line 223

Notice: Undefined offset: -1 in /var/www/vhosts/comap-sas.com/httpdocs/wp-content/plugins/elementor/includes/base/controls-stack.php on line 695

Notice: Trying to access array offset on value of type bool in /var/www/vhosts/comap-sas.com/httpdocs/wp-content/plugins/elementor/includes/base/widget-base.php on line 223

Notice: Undefined offset: -1 in /var/www/vhosts/comap-sas.com/httpdocs/wp-content/plugins/elementor/includes/base/controls-stack.php on line 695

Graphite electrodes

Due to its high conductivity at high temperatures, the graphite electrode is an essential consumable in the electric smelting industry. Graphite electrodes are used in electric arc furnaces and ladle refining furnaces to produce steel, but also for the production of ferroalloys, silicon, phosphorus, corundum and other minerals.

Graphite electrodes, due to the conductivity of graphite, release high temperature arcs to heat the solid scrap to reach the melting stage.

Graphite electrodes have excellent properties such as:

- Electrical resistivity

- Thermal conductivity

- Heat resistance

- High mechanical strength

- Corrosion resistance

Graphite electrodes have various qualities depending on their application and the constraints of the furnace: RP, RPI/HD, HP, SHP, UHP.

Graphite electrodes properties

- Electrical resistivity: This parameter determines the performance of the electrode, the electrical current capacity. Lower is the resistivity, higher is the density, better are the performances of the graphite electrode.

- Thermal conductivity: This property determines the amount of heat transferred from the electrode to the molten material. A high thermal conductivity results in faster melting and a gain in energy.

- Microstructure: which includes both graphitic and fibrous structures. The structure of the graphite has an influence on the properties of the electrode and on its performance in use. A good quality graphite electrode will have a smooth, homogeneous surface with a finer grain size to ensure better electrical resistivity and thermal conductivity.

Quality of graphite electrodes

- UHP ultra high-power electrodes

- SHP super high-power electrodes

- HP high-power electrodes

- RPI regular power impregnated / HD high density electrodes

- RP regular power electrodes.

Graphite electrodes are manufactured from high grade raw materials such as petroleum coke, needle coke and coal tar pitch. These raw materials are carefully selected according to their chemical composition, grain size distribution, carbon content and purity level to ensure that the electrodes fulfil all requirements for strength, flexibility, hardness, and other properties.

To produce high quality graphite electrodes, our producers use the most up-to-date technology and facilities, and carry out strict and regular quality controls during the selection of raw materials and at all stages of the production of graphite electrodes to meet the industry standards.

Graphite electrodes are widely used in various industries such as iron and steel, non-ferrous metal production, mineral production, chemical production, etc.

Some of the key factors in selecting a good grade of electrode include:

- Electrical resistivity

- Thermal conductivity

- Density

- Thermal coefficient of expansion

- Mechanical strength

Manufacturing process of graphite electrodes

To produce a quality graphite electrode, each step of production is important: raw material selection, calcination, dosing, blending, pressing, baking, impregnation, graphitization at temperatures above 3000°C, and then precision machining.

When purchasing graphite electrodes, buyers should carefully consider these factors before making a decision.

With over 35 years of continuous involvement in the graphite electrode market, we can provide strict control over raw material selection, technical support, availability of goods and competitiveness in price. COMAP has a strict quality control during the whole production cycle (density, dimensions, resistivity etc.).

Contact your COMAP expert to find out more about our graphite electrodes of all qualities!